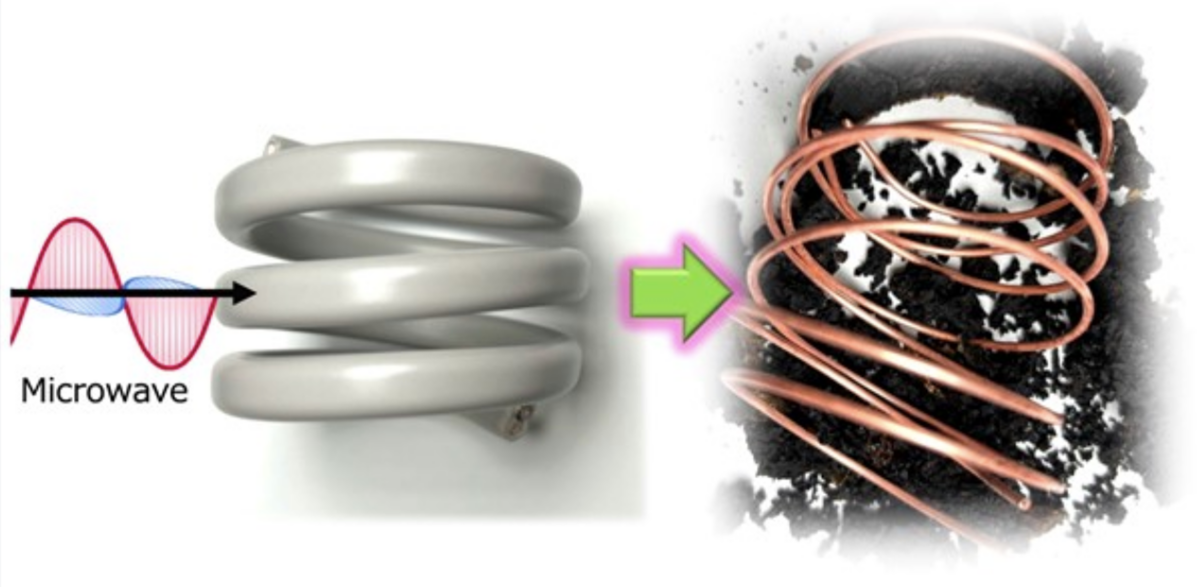

The method developed by the researchers involves placing VVF power cables in a glass reactor where they are subjected to microwave radiation. The pyrolysis carbonizes the PVC insulation, exposing the copper wire and allowing it to be easily recovered.

So putting cables in a microwave to melt the plastic?

This was achieved without the generation or use of toxic chemicals. The researchers explain that during the pyrolysis, the PVC insulation underwent rapid dichlorination and carbonization, which prevented the formation of harmful byproducts such as tar, polycyclic aromatic hydrocarbons and dioxins.

This may be an improvement…

This needs to be styropyro’s next video with his monster microwave generator

While this might be an improvement over chucking cables onto a bonfire but i think it’s unnecessarily high tech. If the cables already need to be cut laterally into specific sections to conform to the wavelength and it uses 200w, then a better design would be to pull the cable over a blade to part the sheath like a hot dog bun. You could do that with a fraction of the power, no emissions from the pyrolysis and simpler more available tools; just some dies/jigs, blades and a motor. It could even be hand cranked. This isn’t something that would get research funding though. And I bet there is already a tinkerer doing it somewhere in a shack in Ghana or Pakistan.

BigStackD on YouTube has an electric cable stripper, which does exactly this, automatically and quickly! It’s really cool.

hell yeah, then we can just chuck the plastic into the ocean. easy-peasy!

😆the plastic does not disappear just because you melt it using a microwave. Or have I understood something wrong?

yes, you missed the important bit. the plastic is carbonized, skipping the processes/stages that would create intermediary, poisonous chemicals.

And what do you do with this carbonized plastic? Or is it a way to get CO2 out of the air? Or is the example above hust not feasible because it is hard to automate?

ha, you really need to ask about what to do with pure carbon?

these are just scientists attempting to find a way to extract precious metals without destroying the environment. dont chase the perfect ignoring the good research.

Wish they had chosen a better title for the article…

That’s very time consuming though. I think the idea is to incentivize recovery for large amounts at once, and quickly. A Glass Reactor size vessel is not very big though…

Is it time consuming though? You could probably feed it through a cutting jig at tens of centimeters per second or more, and as the other commenter said you have to cut the cables into small pieces anyways for the microwave processing.

Well, you’re assuming this is all flat, unbent wiring. When this stuff is scrapped, it’s just a folded mess or ball. They want to just take a big junkyard mess of wiring and melt all the plastic off without any toxic byproducts, then recover the copper.

They want but they can’t (yet)

If no harmful byproducts are produced, can we this to evaporate Plastic?

That’s the problem. If you’re evaporating plastic then you’re definitely releasing a multitude of chemicals; some of which would likely be harmful. Since this is to be performed in large quantities that could be a significant amount of pollution.

This was achieved without the generation or use of toxic chemicals. The researchers explain that during the pyrolysis, the PVC insulation underwent rapid dichlorination and carbonization, which prevented the formation of harmful byproducts such as tar, polycyclic aromatic hydrocarbons and dioxins.