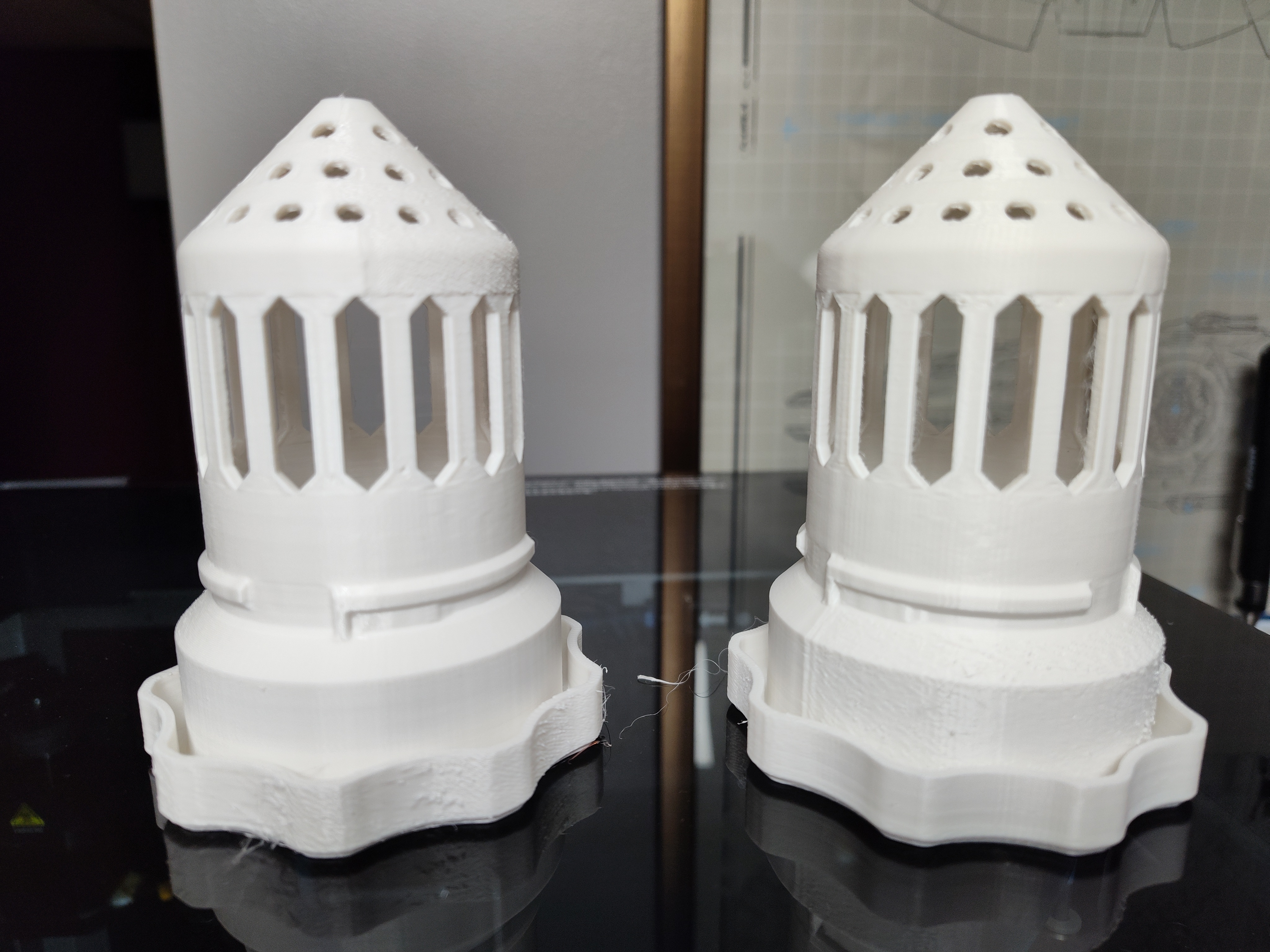

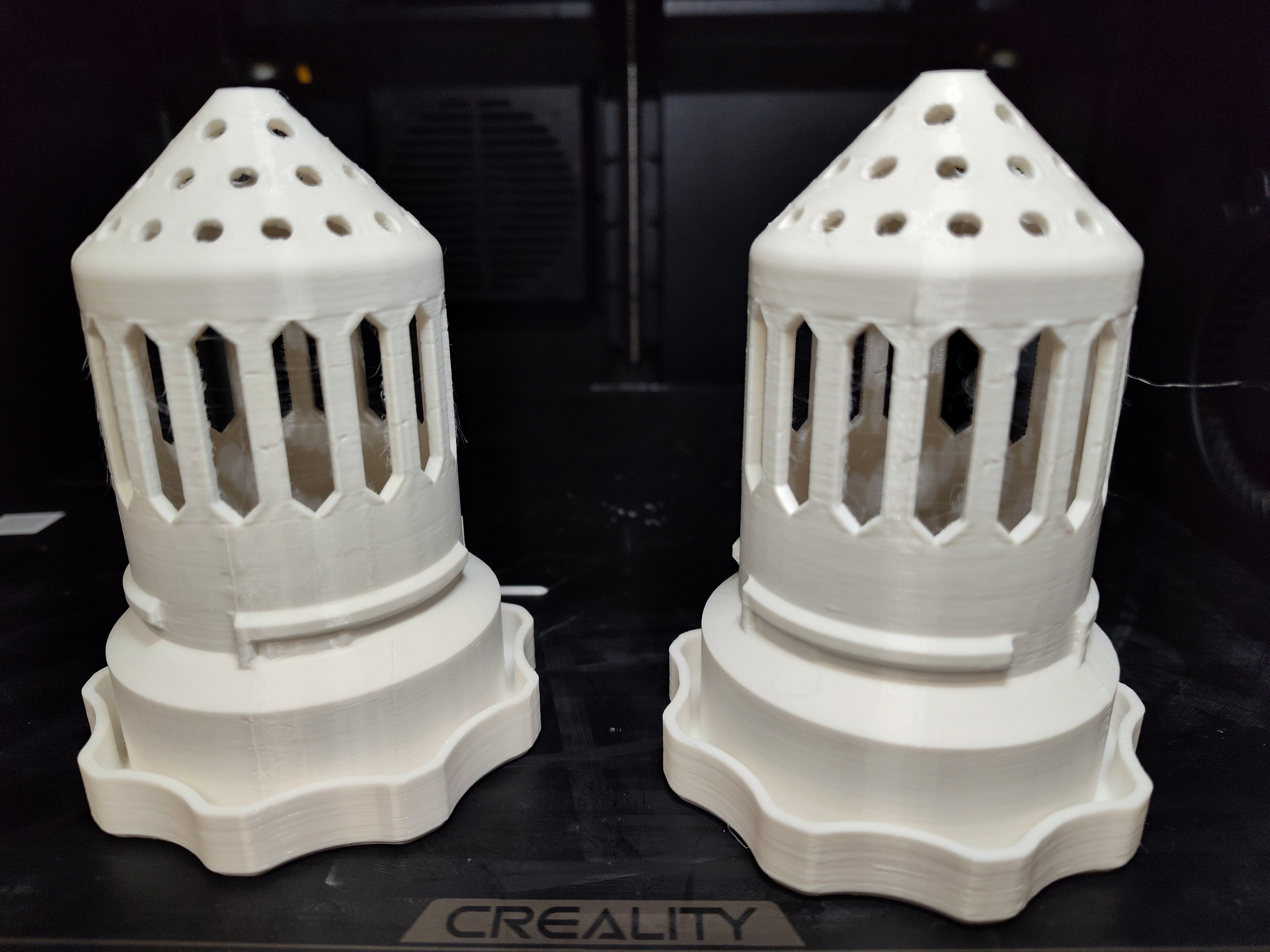

I have a K1 Max and mostly it is running great, however I get strange artifacts on mostly only the front side of curved objects.

I have lubed all the rods, and I have a Capricorn PTFE tube from the filament sensor to the hot end. I tried the printable guide for the tube to go into the hot end but it wasn’t any better and I thought that was the culprit at first.

I have an extension piece to raise up the top glass.

I’m using Elegoo Rapid PTEG running at 240c and 250mm outerwall speed. This is mainly happening on the front side and anywhere on the build plate. Filament is dry and fed out of the Creality Space dryer.

These items are small netcups but it was also happening on the larger sections that they go in.

Using Orcaslicer and Arachne wall generator.

Any ideas where I need to be focusing my attention on?

have you checked belt tension to make sure it’s not too tight or too loose?

Either or could be introducing artifacts.

After that, I would look for anything in the mechanical system that could introduce slop.

if the machine is nice and mechanically well tuned, I would consider running a quick temp tower to verify that you’re printing at the right temperature. if it’s not that, I would blame the slicer.

that said, do the net cups fit? they don’t have to be pretty.

My brother was trying to print these, and kept having problems using cura; where the corners of the net-hole-thingies caused slicing artifacts and under extrusion. I could never talk him into trying the fuzzy-skin-spiral-mode alternative i came up with. (fuzzy skin is a random “experimental” feature that I found makes for a great mesh filter when printed in spiral.) (i mean I can’t even get him to give up cura for prusaslicer)

Thanks for your reply, to your point yes they still fit, been having this issues for a bit now as I’m up to about 40 of these netcups and the associated other pieces for the grow towers.

I think the belts are good, but will double check.

to clarify, other parts that aren’t related to the model, do they print fine? or is it just these pairs of models?

it could be the mesh you’re dealing with is corrupted.

Good point, I have mainly been printing these items for the hydroponic tower. I do have other versions that I can check. I think after this set prints I will add some basic shapes in different orientations to see if there is issues still.

That being said I did print some other items that were stacked and each one is much thinner but there are no artifacts on the outer walls.

Could try rotating the model 90°. If the issues remain in the same location, you’ll know it’s a printer issue, maybe due to the size of the radius.

So I sliced and printed a different model, and then rotated 1 by 180°, it is somewhat weird as the lowest part on the right model seems ok but as the wall built up on the inside it was getting the artifacts. The model on the left was getting the artifacts on the outer piece but not the inner.

In rotating the models after, the artifacts are on the opposite side.

I noticed it was starting at the seam, I have the scarf joint on contour, and noticed that “scarf around entire wall” was checked so trying reprinting to see if that is the issue.

Well that was the problem, thanks for everyone’s input.

deleted by creator

The K1 series has graphite bushings on the X axis which should be self lubricating and should not be greased.

I re-lubed the rods before starting another set and still having the issue. I was thinking it had something to do with the Bowden tube but even at the back where the tube doesn’t move much the issue still happens.

Is there a specific lube that is better than others?