I actually did need to take a hacksaw to a Dell case when the PSU died, because they used a proprietary form factor. It was just removing some of the back panel and it worked fine.

Once upon a time I think they also had custom pinouts on the ATX connector, so just replacing your PSU with a standard one would fry your mobo

What a bunch of assholes.

They did, I was about to say the same thing! I had to buy an adapter to make it work right. This was like mid to late 2000’s. I work in IT for a company and didn’t want to spend money on a new PC yet so I snagged one from work that was no longer used. It got the job done, but yeah it was crazy to see what they did to make it so you couldn’t swap or change some things inside.

Fuckin pricks turning the goddamn cpus 45° so no cooler would ever fit… grrr

Yeeeep. I did this. Very disheartening after spending the time with a Dremel to modify the back panel enough for it to fit.

Reminds me of when I made a pc as a media center for my roommates out of old spare pc parts and the box that their xbox360 came in.

Had to turn it on by using a paper clip to short the right two pins, lol.

to short the right two pins

That’s the core principle of how switches work. You have done everything right.

Legit badass. “Hotwire the PC so we can watch a movie!”

You know, you could have run down to the electronics store and bought an actual button for those pins. Still, that sounds like a fun build.

I test-“built” my first gaming pc with all the parts laying on my bed.

The only computer parts store within cycling distance just put returned parts back on the shelf, so there was about an 80% chance at least one part you bought was dead out of the box.Later I remembered that that’s possible, and built a gaming rig with all parts mounted openly on the wall behind my desk.

If it’s stupid and it works…

“Tech hack”

So it isn’t stupid anymore, but they could just find a random full size pc case somewhere and use it instead of this.

It’s an OEM motherboard and it may not be a normal standard. The PSU isn’t normal either so it wouldn’t fit most *ATX cases. Plus, free is free.

OEM mobos suck. Boards from this era of Optiplex are pretty standard apart from the PSU connector, but newer ones have motherboards that go all the way from one side of the chassis to the other, and mount the power button and front panel I/O on the mobo. I don’t even know if they have internal USB headers.

I thought dells aren’t as shitty as the competition, as I have a great experience with a Latitude 5290. I guess I was wrong.

They’re not shitty. HP, Lenovo do the same shit - proprietary motherboards, limited feature sets, and minimal upgrade paths are typical of OEMs… It’s also why a lot of people recommend building to anyone.

I don’t know why but this has me rolling. Genuinely had to catch my breath.

Happy to know my redneck engineering made you laugh! It was either that or a custom water loop.

If it’s stupid, but it works, it’s not stupid.

i mean there are things that work and that are stupid, and will stay stupid. using toothpaste for example as thermal paste is doable and you can get usable temps with it. but the con is that toothpaste dries up very quickly, requiring you to need to constantly reapply it.

it works, but its still a stupid idea.

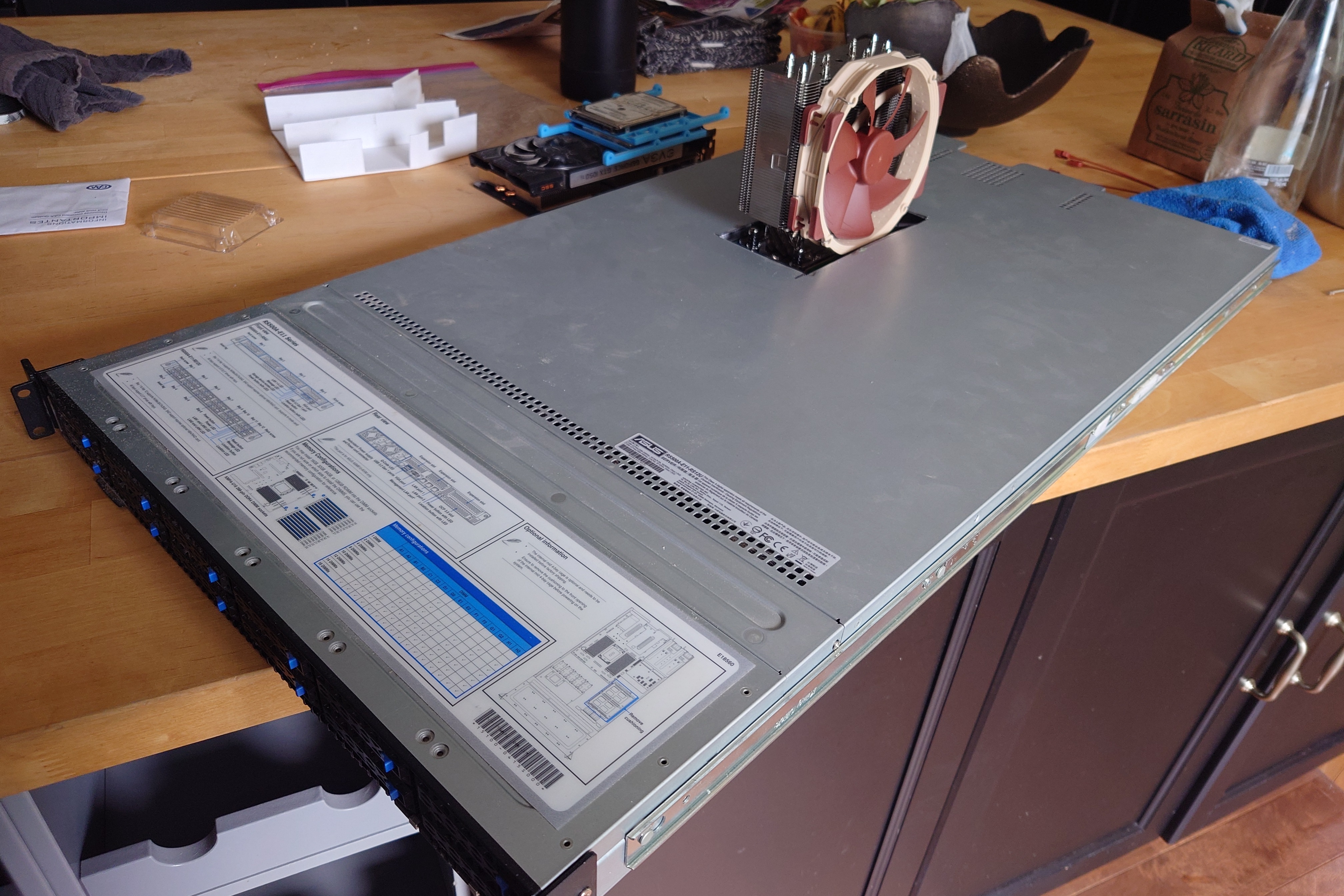

That probably worked way better than having it in a thermally constrained environment.

It’s also way more quiet than those damn pesky 1U fans and I had the space available in my rack

Is that some kind of blade server? Doesn’t that make it like not rack with other blades?

No it’s just a 1U server. It does mean that the next 3U over the server can’t be fully used (switches would probably clear). That server pretty much replaced my whole stack except for my NAS so I had space available.

So … you have to remove your CPU cooler to open the case? That does not look very convenient.

The top has just enough slide room to disengage from the chassis and be pulled upward. Being able to hotswap components is a requirementfor my case.

I guess airflow is airflow, don’t matter which way

Like a hotrod?

Exactly!

Yup, the back plate for my CPU cooler wouldn’t fit because of some weird struts my case has, so I cut open the case, just enough to fit it.

Literally thinking outside the box.

This is the dude I’d turn down any 1v1 Starcraft matches against at the lan party.

It’s a Dell Outieplex.

Lol, nice one

This makes more sense. I worked with those so much

“Think outside the box.”

Why even bother putting the side cover back on? I left mine open for years.

maybe pet hair? dust? maybe they get laid?

You’re talking about three different things, right? … right?

I toucha da

fishcat.

hey if you can sexually satisfy dust and cat hair, you should consider starting an onlyfans. while the human brain often confuses sneezing for orgasms, it’s only partial credit.

They’re a pc gamer, they sure as shit ain’t getting laid.

Put energy into women, or put energy into Helldivers.

I’ve been through enough trauma to know that Helldivers is way healthier

Probably sound mitigation

Fuckin’ eh. My power supply is slung out the side to make room for a video card, with the case panel resting askew on top all perched on a milk crate. Like a slasher flick autopsy.

I did this, except in a cardboard box, plugged into an outlet with no ground, and using it to mine cryptocurrency. Somehow I didn’t burn down my apartment.

I have enough money for an angle grinder and a new used graphics card. But not a fancy new case.

With prebuilds like this a lot of times you can’t just change the case without also changing the motherboard. Also they could have an angle grinder just laying around. They may even have done it on purpose for the lulz.

I actually just upgraded my Dell Optiplex 990 SFF to a new full ATX case and had to get a new motherboard. Dell does some funky stuff to their motherboard to get it to fit into their custom cases. For instance the CPU cooler clipped into the case through the motherboard This was one of the ways the motherboard was secured into the case. The other mount points were entirely non-standard so no other case would fit. I did consider making some modifications to the case with a hacksaw before deciding to just get a new case and motherboard. The new Motherboard was pretty cheap because I was using a 4th-gen intel i3. Not great specs but good enough for a homebrew NAS.

Yes, from experience, yes. But I used a pair of tin snips.

“Dude, you’re getting a DELL.”

gettinggutting (or cutting)

How did you get a picture of my PC!?

I joke…I at least 3d printed a cover for the card lol

That PLA is melting as we speak.

Pet-G brah, only the good stuff

The hole in the side is a speed-hole. It makes the computer go faster.

It was such a good deal bro I had to buy it! 😂

If you’re on a budget and it works…